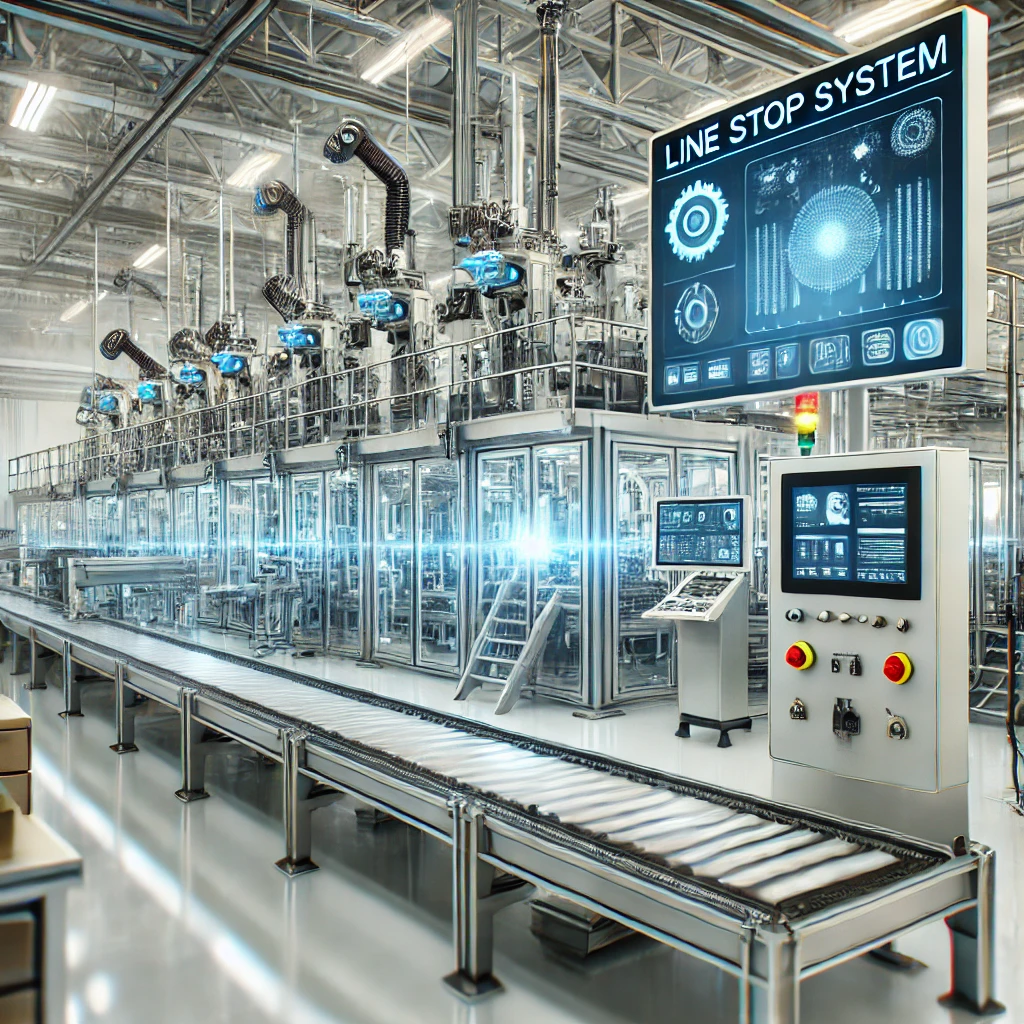

Optimize OEE with Smart Line Stop Systems

Smart Line Stop Systems are transforming the world of industrial manufacturing, achieving maximum efficiency in every production operation. The automated line stop recording system we developed is an advanced solution designed to strengthen Lean Manufacturing principles and enhance Overall Equipment Effectiveness (OEE). Through the integration of this technology, we aim to reduce waste and maximize machine productivity.

Understanding the Automated Line Stop Recording System

This system utilizes advanced sensors installed on each machine. These sensors detect the presence of products passing through. If a machine exceeds the designated production time for a product without yielding results, the system automatically records this event as a machine stoppage or line stop. This recording process occurs in real time, ensuring every second of machine activity is accurately documented.

Each product has a production time limit or cycle time that can be set within the system, tailored to the specific production needs. This precision is crucial for maintaining production rhythm and quickly identifying deviations.

Visualization and Management of Line Stops

We use an intuitive bar chart visualization, where red indicates a machine stop and green indicates the machine is operational. This visualization simplifies machine monitoring and enables quick identification when a line stop occurs.

When a stoppage happens, operators can immediately identify and address the issue by clicking a button already available and connected to the system. The speed of this handling is crucial for reducing downtime and enhancing efficiency.

Automated Recording and OEE Enhancement

This system significantly contributes to enhancing OEE, a key metric in Lean Manufacturing that measures the total effectiveness of equipment. By documenting each line stop and its cause, the system helps minimize downtime and increase effective production time. Reducing downtime directly impacts the improvement of machine availability, performance, and production quality.

Tiered Notifications via WhatsApp for Line Stop Management

In our continuous efforts to enhance communication and responsiveness to line stop incidents, we have integrated a tiered notification feature via WhatsApp into our automated line stop recording system. This feature is designed to provide real-time updates to relevant teams, ensuring that each incident is addressed promptly and efficiently.

How WhatsApp Notifications Work

- Determining Notification Recipients:

- System administrators can configure who will receive notifications. This could include line supervisors, maintenance technicians, or factory managers. The settings are flexible and can be customized based on the specific needs of each production line or department.

- Selecting Line Stop Types:

- Not all line stops require immediate attention. Therefore, the system allows users to specify which types of line stops will trigger the sending of notifications. For example, line stops due to mechanical issues or material shortages may require quicker responses compared to routine maintenance stops.

- Notification Frequency:

- Users can set the intervals at which notifications should be sent. This is crucial to avoid information overload. For instance, if a line stop lasts more than 5 minutes, the system will automatically send a notification. If the machine resumes operation and then stops again, the timer will reset, and a new notification will be sent according to the predetermined interval settings.

Implementation and Benefits of WhatsApp Notifications

WhatsApp notifications offer several advantages:

- Rapid Communication : WhatsApp is a widely used platform that enables instant messaging, ensuring that all relevant parties receive timely information.

- Automated Documentation : Every notification sent is recorded in the system, providing complete documentation of how and when each line stop incident is handled.

- High Responsiveness : With timely notifications, the maintenance team can act quickly to fix issues, reduce downtime, and enhance productivity.

- Flexible Customization : The system allows for customization of notifications based on the severity and type of line stop, making it highly effective in managing emergency situations.

The integration of this WhatsApp notification feature demonstrates our commitment to leveraging technology to support production efficiency. With this system, every element of production is maintained to operate smoothly and effectively, supporting the achievement of higher production targets and enhanced operational efficiency.

Comprehensive Reports for Analysis and Continuous Improvement

At the end of each shift, the system generates a detailed report that includes the number and duration of line stops that occurred. This report facilitates deep analysis and the design of continuous improvement strategies, in line with the kaizen philosophy of Lean Manufacturing.

Conclusion

The adoption of this automated line stop recording system not only helps in reducing downtime but also ensures that production operations are more streamlined and efficient. With accurate documentation and real-time analysis, every aspect of production becomes more transparent and can be optimized. This represents a step forward in manufacturing technology, supporting your efforts to achieve excellence in production.

The Andon System developed by Karsatech is equipped with a WhatsApp notification feature, so that any issues related to machine malfunctions can be immediately reported to the supervisor or management responsible for the production process involving the machine.